Predictive Maintenance

Discover the benefits of predictive maintenance with Elazur

What is predictive maintenance?

The reactive maintenance is an eventuality that can never be categorically ruled out, and continues to be considered acceptable within a company if the replacement of components is strategically opportune in terms of cost, if the failure does not lead to further damage, and above all, if safety is not jeopardized.

Planned maintenance involves replacing components that are still functional, at intervals based on statistical data on service life.

Understood in this way, this strategy is controversial in many aspects, particularly when it comes to transforming parts that are still functional into waste and managing spare parts.

With the maturation of the fourth industrial revolution, digitization and connectivity have made procedures that were previously only theoretically practicable, enabling easy and immediate management of the detection, archiving, and monitoring of the data needed as an information base for programmable maintenance activities, and not just to be carried out after a breakdown. The use of robotized machines in manufacturing industries and the potential of artificial intelligence in this field have already taken maintenance from the programmatic level (already pursued with the second industrial revolution) to the proactive and predictive .

Predictive maintenance is an approach to maintenance management that involves to predict potential equipment or system failures before they occur. Rather than following a fixed schedule for preventive maintenance or reacting to unforeseen breakdowns with corrective maintenance, maintenance Predictive maintenance uses real-time data, sensors, analysis, and algorithms to anticipate maintenance requirements.

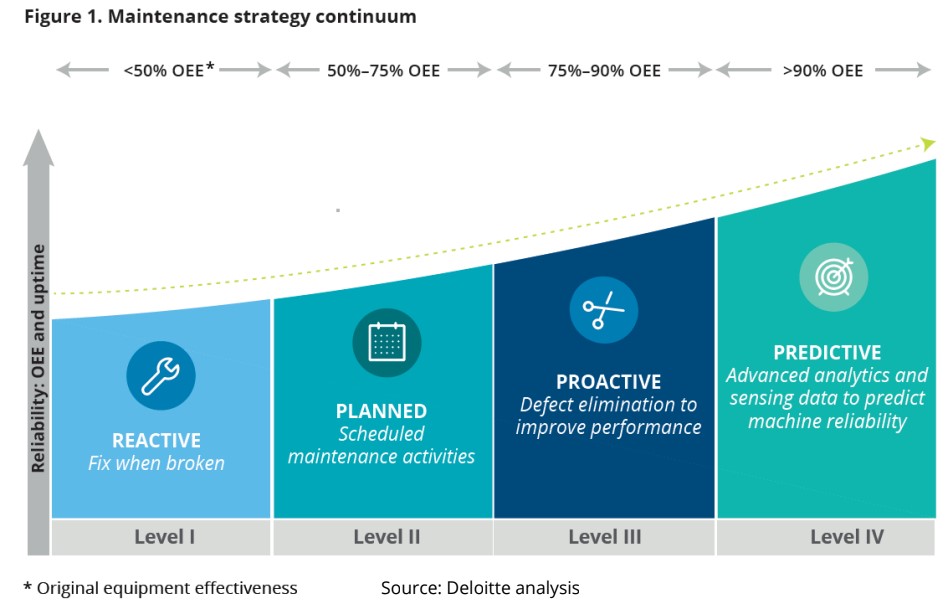

ELAZUR’s aim is to help your organization move towards predictive maintenance. But you can’t do it by jumping the gun. This graph illustrates the road to predictive maintenance.

ELAZUR, thanks to its maintenance experts and its ePlanner business tool, which automatically plans and schedules your WO, helps you move towards planned maintenance. This is the logical and essential step towards predictive maintenance.

The key points of predictive maintenance

Real-time monitoring

Use of sensors and devices to collect real-time data on equipment performance and operating conditions.

Data analysis

Application of advanced algorithms, machine learning and statistical analysis to interpret collected data and identify patterns or precursor signals of failure

Failure prediction

Ability to anticipate potential failures based on the results of data analysis, enabling proactive intervention before a breakdown occurs

Reduced downtime

By identifying and correcting problems before they lead to major breakdowns, predictive maintenance helps minimize unplanned downtime

Resource optimization

Concentration of maintenance efforts on equipment that really needs them, enabling efficient use of human, material and financial resources

Reduced costs

Reduced costs for emergency repairs and replacements in a systematic way and production losses, thanks to more efficient scheduling of maintenance operations.

Extended equipment life

By identifying and correcting problems at an early stage, predictive maintenance can help extend the useful life of equipment.

Improved safety

By identifyingrisks and intervening proactively, predictive maintenance helps to improve the safety of industrial operations.

Integration of advanced technologies

Use of technologies such as the Internet of Things (IoT), cloud-based data analysis, artificial intelligence and machine learning to improve prediction accuracy and overall system performance

Strategic planning

Enables strategic business planningandreduced downtimebased on objective data rather than fixed schedules, optimizing operational efficiency

- Elazur has been the link between your business and specialized asset management applications since 2016

Partners & Customers

Experience and skills in implementing predictive maintenance

With its proven expertise, ELAZUR has demonstrated its excellence in implementing EAM solutions to help their customers move from reactive to predictive maintenance, combining in-depth business experience with cutting-edge skills.

Join many supported companies

FAQ - ELAZUR Answers your questions

Predictive maintenance is an approach to maintenance management that aims to predict potential equipment or system failures before they occur. Predictive maintenance is a proactive strategy that uses real-time data to anticipate equipment breakdowns, thus minimizing unplanned downtime.

Predictive maintenance reduces operating costs, extends equipment life and minimizes production downtime.

Technologies include sensors, the Internet of Things (IoT), advanced data analysis, and specialized software to monitor and predict failures.

ELAZURthanks to its maintenance experts and its ePlanner business tool, which offers a planning automatic and prescription your WO, helps you switch to planned maintenance. This is a crucial step to a predictive maintenance.

Contact our experts for a chat. We will guide you to switch from reactive or predictive maintenance to planned and predictive maintenance in your operations, maximizing its positive impact.